Hydrocon Green is the sole Roediger Vacuum Systems partner in Botswana.

Roediger vacuum systems are a cost effective alternative to gravity sewer systems.

Vacuum systems are particularly attractive in environmentally sensitive areas and when difficult subsurface conditions exist such as high groundwater table, unstable soils, rock and restricted construction conditions.

-

- Cost savings due to smaller pipes, shallower and narrower trenches, less dewatering and significantly less surface restoration… all done with smaller Equipment!

- Only 1 source of power is required at the vacuum station. A standby generator at the vacuum station provides uninterrupted service during power outages. No power is required at the house/valve pit.

- Operator friendly as the operator never comes in contact with raw sewage. Confined spaces are not an issue.

- Environmentally friendly as the system is entirely closed which not only prevents leakage but also infiltration and inflow. This also results in a reduced load on the treatment plant.

- Multiple lift stations can be replaced as it is not uncommon for one vacuum station to replace 6-8 gravity lift stations.

- Cost overruns avoided due to vacuum’s vertical and horizontal routing flexibility which allows unforeseen underground utility conflicts to easily be avoided.

What is Vacuum Sewerage?

What is Vacuum Sewerage?

A vacuum sewer is a waste collection system which uses a pipe network, under a negative pressure ‘vacuum’, to transfer waste from households to a vacuum station, where it is pumped in a conventional method to a sewerage treatment plant.

-

- Where would vacuum sewerage be feasible / suitable:

-

-

- Where the topography is very flat

- Where sub surface soil is difficult / dangerous to excavate (rock / soft sand).Vacuum systems are typically installed between 0.5 and 1.5m from the surface. There is no need to create a slope as the vacuum moves the waste.

- Where the provision of electricity is limited – A vacuum system only requires electricity at the vacuum station, the chambers and pipe network, do not require electricity

- Where there is existing infrastructure, such as roads and other networks.

- Vacuum pipes are small diameter and can be designed to work around obstructions in the ground.

- Can be installed on the side of a road, therefore causing minimal interruption

- Construction period is shorter, as the civils works are not as significant

- Where ground contamination is sensitive – Vacuum is a closed system, so there is no leakage, exfiltration or odour.

-

How does Vacuum Sewerage work?

There are 3 areas that make up a vacuum sewerage system:

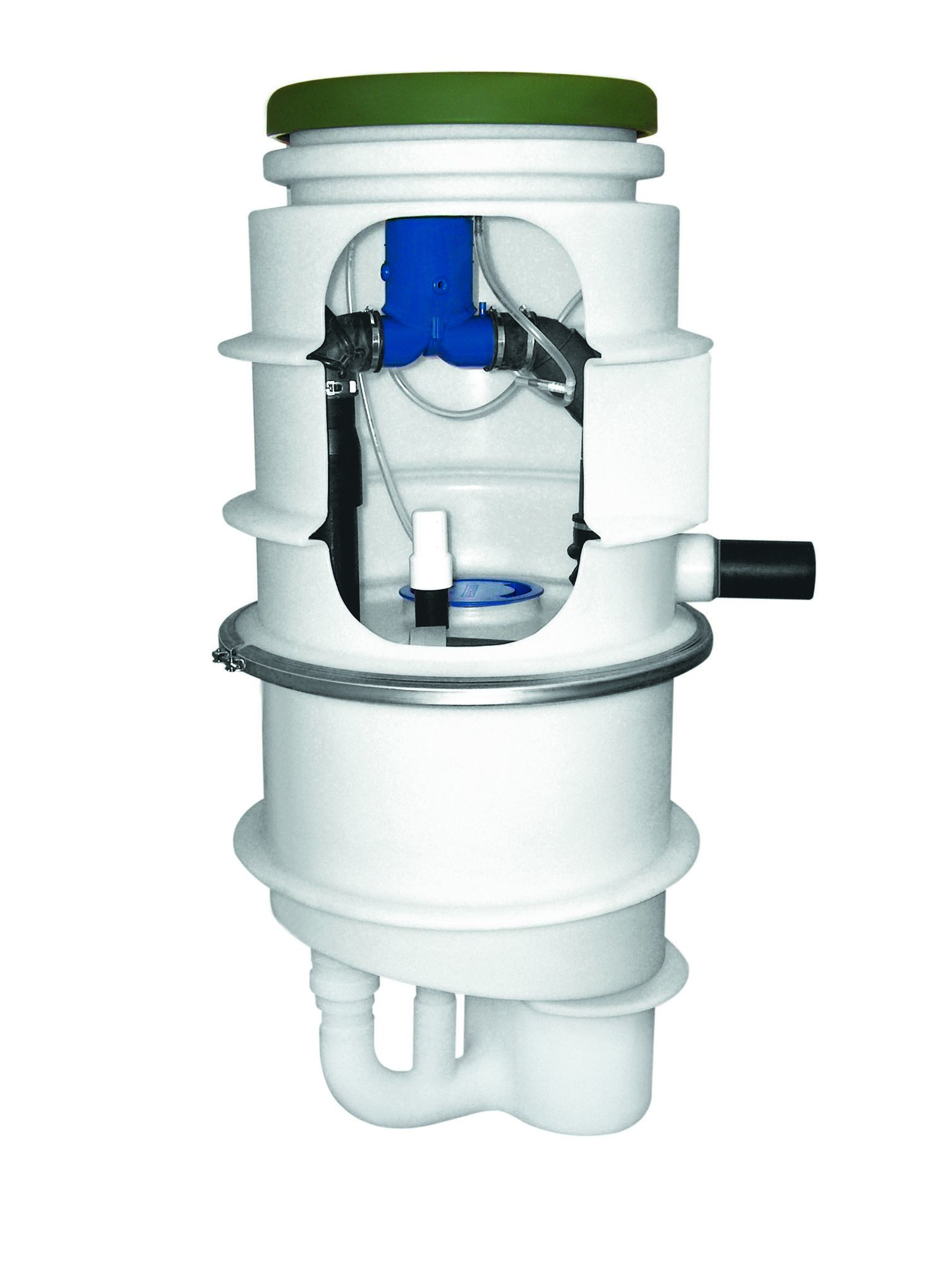

- The Chambers

The waste from a household gravity drains into a chamber.

-

- The chamber receives the waste and when the quantity is sufficient it releases the waste into the network

- The Roediger chambers operate on a combination of atmospheric pressure and waste levels. Once a predetermined level is achieved within the chamber, the Roediger Controller opens the Roediger valve, which allows the vacuum to evacuate the waste from the chamber, into the network.

- Once the waste level is emptied, the valve closes, rendering the chamber vacuum-less again.

- This cycle is continuous when ever the chamber is being used, it can also remain dormant without any adverse effects.

- The chamber does not require any electrical connection

- Chambers can be fitted with a monitoring device which gives performance feedback and sends notifications should maintenance be required.

2. The network

-

- The pipe network operates under a negative pressure, using air to create a vacuum.

- This vacuum and the saw tooth profile of the pipe network, propels the waste, through the network at high velocity, until it is delivered to the Vacuum station.

- The network does not require any electrical connections

- The network does not require any lift stations

- The network does not require any manholes

- The network is flexible and can process waste uphill and or under / around obstacles.

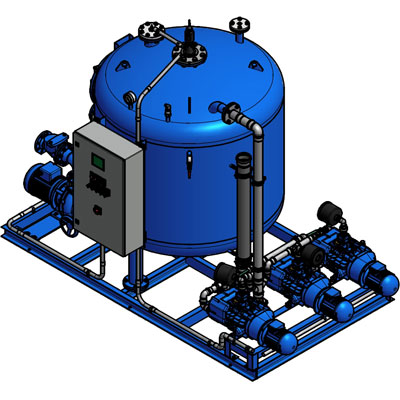

3. The Vacuum Station

- Comprises of:

- A set of vacuum pumps which generate the vacuum within the network

- A vacuum chamber which receives the waste

- A set of discharge pumps to discharge the waste to the STP

- A bio-filter which manages the exhaust odours

- A control center which manages and records the pump & system performance

- The monitoring control cente

Projects – Botswana

Shoshong

- Pipeline Network 55 KM

- 6 Vacuum Pumps

- 3 Discharge Pumps

Good Hope

- Pipeline Network 11.3 KM

- 3 Vacuum Pumps

- 2 Discharge Pumps

Jwaneng

- Pipeline Network 16 KM

- 4 Vacuum Pumps

- 2 Discharge Pumps

Ghanzi

- Pipeline Network 2.6 KM

- 2 Vacuum Pumps

- 2 Discharge Pumps

What is Vacuum Sewerage?

What is Vacuum Sewerage?